Take Field Service To The Next Level

Refusing to settle for ‘good’ service levels, this document solutions provider upgraded its field

service solution and enhanced technician productivity.

When evaluating field service management software platforms for its handheld-based solution, Danka Business Systems ultimately selected Astea FieldCentrix FX Mobile software. FX Mobile is a workflow software product that uses wireless communications with handheld computers, laptops, and PDAs to automate field service processes and help field personnel perform their jobs. With FieldCentrix' mobile client technology, field service technicians are able to complete work, uninterrupted, regardless of wireless coverage. Along with FX Service Center, FX Mobile eliminates the manual inefficiencies and paperwork that can overwhelm service technicians. With FX Mobile, technicians receive work orders electronically on their mobile devices. It then guides them, screen by screen, through the job — prompting them to perform standard tasks, take notes, and even record future recommended repairs or activities.

While Astea FX Mobile software certainly met Danka's needs, so did several other software products on the market. Ultimately, Danka selected Astea for the project because of the vendor's visible commitment to the Danka initiative.

"The core platform capabilities of several field service software solutions on the market are all similar," says Michael Calcinari, VP of service planning and support at Danka. "However, Astea flew one of its chief integrators to our facility to get an in-depth understanding of our processes and business requirements. Furthermore, Astea's entire project management team was willing to work with us on a number of software customization requests that were vital to the ultimate success of the deployment. These were the real reasons we decided to work with Astea."

One of the most important software customizations Astea worked on with Danka was a mechanism that replicated the Danka parts item master (which includes more than 400,000 line items) so it is accessible from the Motorola MC70 handheld device. This customization was instrumental in providing Danka field technicians with a totally disconnected and independent user experience. This capability ultimately enhanced technician productivity and reduced the number of tech center calls.

For more information on Astea go to www.astea.com

Most companies would consider a 93% transaction automation rate to be an acceptable, if not outstanding, measure of field service efficiency. Danka Business Systems, however, isn't like most companies. This provider of document management solutions, including copy machines, printers, and other office equipment, was achieving this impressive transaction automation rate from an IVR (interactive voice response) system it relied on since 1997 — and wasn't satisfied.

"There is a great deal of competition in our industry, and the technologies and products we sell evolve rapidly," says Michael Calcinari, VP of service planning and support with Danka Business Systems. "These factors make service a key competitive differentiator. To ensure we stay ahead of the pack, we need to continuously strive to achieve new levels of performance and enable our field service technicians to deliver more services on a timely basis."

With this philosophy as motivation, Danka upgraded its field service automation solution in 2006 — moving from an IVR system to a solution consisting of handheld computers and field service software. Many might consider a solution overhaul such as this to be a risky proposition, but Danka was able to orchestrate the change to its advantage — leveraging the new system to reduce operating costs, increase field technician productivity, and improve customer service.

HANDHELD COMPUTER INTERFACE ENHANCES USER EXPERIENCE

Danka maintains a field service organization of more than 1,000 employees to provide standard break/fix and networking services for the office equipment it sells to clients throughout the United States. As mentioned, Danka implemented an IVR system in 1997 to enable its field force to automate many service tasks including call queue management, parts ordering, and call debriefing. This system allowed Danka's field technicians to complete most of their service transactions by responding to automated attendant voice prompts using the touchtone keypad on a cell phone. An estimated 30 million transactions were handled by the IVR platform over a period of nine years.

While the IVR platform met many of Danka's field service automation requirements, the solution's interface had limited inventory and parts order capabilities. "While it was possible for the IVR platform to provide inventory lists, listening to a machine speak 200 part numbers would be a time-consuming and unsatisfying user experience," says Calcinari. "For a number of years, we had envisioned a gradual evolution from our IVR system to a solution based on handheld computer technology. We felt a solution with a GUI [graphical user interface] could potentially provide our technicians with more real-time information and decrease their overall dependency on our call center."

In fact, when Danka upgraded its IVR platform in conjunction with the launch of a new Oracle ERP (enterprise resource planning) system in 2000, it established a field service technology road map. This road map initially included several incremental upgrades to the IVR system — including porting the IVR functionality to a Web-based platform — before ultimately transitioning to a handheld computer solution with network connectivity. As it turned out, rapid technical advancements to handheld computer technologies, combined with competitive pricing of the devices, allowed Danka to skip many of the incremental IVR upgrades and move right to the final step of the road map by June 2006.

START WITH HARDWARE WHEN BUILDING A FIELD SERVICE SOLUTION

While a field service automation solution consists of hardware and software components, Danka began its search for a new technology platform by focusing on the handheld computer hardware first. "We wanted to gain a full understanding of the capabilities of the handhelds before we even looked at software," says Calcinari. "We took this approach for two reasons. First, a feature-rich software platform wouldn't do us any good if we didn't have a hardware device that could support it. Second, it is much easier to alter and customize software to meet your ever-changing business requirements than it is to alter a piece of hardware."

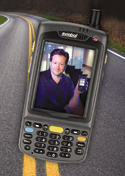

Handheld computer features that were of primary importance to Danka were product size and durability (for convenience and sustained operation in the field), a QWERTY keyboard (to facilitate data entry), all-day battery life, and built-in bar code scanning. Bar code scanning was crucial because of a key step in the service call process that requires a technician to scan an equipment ID tag on each device it services. This step ensures the technician services the right piece of equipment and records a start time for the service performed. Using this set of criteria, Danka decided that the MC70 digital assistants by Motorola would be the best fit for its business needs.

After landing on a hardware device, Danka began an evaluation of five different field service management software platforms. Danka was most interested in software that took advantage of the smart client functionality of Windows Mobile as opposed to a browser-based application. After narrowing the field of vendors based on this criterion, Danka selected Astea FieldCentrix FX Mobile software due largely to the efforts of Astea's project development team (see sidebar on right).

As it turns out, choosing the components of its new automated field service solution was the easy part of Danka's technology initiative. The hard part was justifying the solution's cost to company executives. "We were asking the company to invest hundreds of thousands of dollars in a new solution that, on the surface, would only increase our transaction automation rates by one or two percentage points over the 93% automation rates we were already getting from our IVR system," says Calcinari. "Our executives were willing to look beyond the transaction automation rates and see the productivity and cost savings that could result from the enhanced technician experience that the handheld solution would provide."

To convince company executives to invest in the new handheld-based field service system, Calcinari and his team developed an exhaustive list of ways they thought the solution would pay dividends for Danka over a short period of time. This list pointed to benefits such as:

n Cost savings due to reduced reliance on laptops and lower platform support costs

n Improved technician productivity and parts utilization as a result of the real-time inventory list and part order validation capabilities the handheld solution would provide

n Improved billing accuracy as a result of having real-time part pricing in the field and electronic customer signature capture.

EVANGELISTS AND PROCESSES AID IN FIELD SERVICE DEPLOYMENTS

After being presented with this list of potential benefits, Danka executives approved funding for the new field service system, and Calcinari's team began a phased deployment of the solution in May 2007. The first phase of deployment was the rollout of a beta version of the application to a handpicked group of 25 Danka field team members throughout the United States. This core team of field employees was trained on the system first and served as local leaders and evangelists of the system when it was rolled out in its entirety to each of Danka's 60 regional markets. "Having a select group of employees champion the system and assist in the solution's overall deployment helped facilitate end user adoption and acceptance," says Calcinari.

Another element that aided in Danka's transition from an IVR field service management solution to a system based on handheld computer technology was that Danka had sound field service processes in place before it made the switch in technology platforms. "When we implemented our Oracle ERP system in 2000, we laid the groundwork for service systems that could someday be extended for use by a handheld solution," says Calcinari. "This was all part of the technology road map we put in place at the time. As part of this project we created detailed process documentation for every job that could be performed — field activities, parts management, call dispatch, etc. — and noted exactly where a handheld solution could improve on each process."

CUT COSTS, HIKE PRODUCTIVITY WITH FIELD SERVICE AUTOMATION

Danka completed the rollout of its new handheld field service solution, which it calls Danka ESP (expert service provider), in September 2007. Today, Danka technicians have their own MC70s that they keep with them and charge up at home overnight. Each morning, the technicians log in to the ESP client application and automatically receive an updated parts inventory and their new service calls for the day. Throughout their workday, the MC70 equipped with Astea FieldCentrix FX Mobile updates their service calls, allowing them to react to new call notifications, and provides them with part order status information.

To date, Danka technicians are completing between 3,000 and 4,000 work orders a day using the new field service platform, and the solution has generated some expected, and unexpected, benefits. First, with the MC70s now in use, the company is saving the more than $600 a year in software licensing, antivirus subscriptions, and helpdesk support it used to spend on each laptop it maintained. Furthermore, having real-time access to inventory lists, parts availability, and other key service information has had a profound impact on technician productivity. "Our handheld-based field service solution has allowed us to recover approximately 40 minutes of administrative time per day, per technician," says Calcinari.

The availability of real-time information has also had an unexpected impact on Danka's telecommunications costs. "The availability of key service information via a handheld computer has made our field technicians more independent," says Calcinari. "Our technicians have been able to increase the number of transactions they can perform without the support of a call center agent. This has reduced the number of tech center calls being placed by more than 60%, saving us tens of thousands of dollars a month in telecom charges."

According to Calcinari, another unexpected benefit of Danka's handheld-based field service solution is how it has helped enhance the company's image and customer service. "With our old IVR system, field technicians presented customers with handwritten work orders that were often hard to read when they completed a service call," he says. "With our handheld solution, client signatures are captured electronically directly from the handheld, and work orders are generated in PDF format and e-mailed to the customer at the end of a service call. These PDFs have all the information [e.g. service details, parts used, etc.] neatly typed out and have elevated our level of professionalism."

While impressed with the results it has seen from its new handheld-based field service solution, Danka still refuses to rest on its laurels. The company plans to build on the success of the solution with multiple planned upgrades to the system, the first of which will occur this year. 'Phase 2' of the solution deployment will include further customization of the Astea FieldCentrix FX Mobile software to streamline workflows and reduce the number of clicks necessary to perform certain field service tasks, such as booking the work order and updating estimated time of arrival.