M2M Enables Service From A Distance

By Brian Albright, Field Technologies magazine

More companies with traditional field service operations are taking advantage of the remote service capabilities M2M (machine-to-machine) technology provides.

Enterprise assets are becoming more connected. Lower wireless costs and the advent of cloud-based asset management and maintenance solutions have made it possible for even smaller companies to use remote connectivity and M2M technology to improve asset performance and offer new types of customer services.

According to “The Real-Time Service Enterprise: Leveraging Remote Connectivity to Drive Service Performance,” a research report published in 2010 by Aberdeen Group, 80% of survey respondents had some sort of link to serviceable assets in the field. This is significant growth for what used to be a niche application utilized for high-value assets like medical devices.

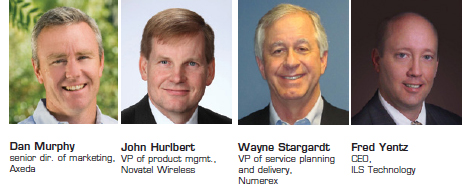

"Early adopters saw the benefit of having real-time information coming directly from the products that they support and service," says Dan Murphy, senior director of marketing at Axeda. "Even more importantly, more advanced Internet-enabled remote service solutions gave these companies the ability to act on that information and send remote updates and fixes that helped them provide faster issue resolution and improved product availability for their customers. Once a handful of companies started to provide this higher level of service to their customers, there was competitive pressure for the others to quickly follow suit."

According to the report, the primary drivers for remote asset connectivity are customer demand for improved service, reducing costs, increased productivity/ efficiency, and the need for increased service revenues. Improved wide-area wireless network performance and the falling cost of wireless data service (as well as the hardware modules needed to enable connectivity) are further driving growth in this sector.

"Historically, wide-area connectivity has been driven by transportation: connected vehicles provide cost savings and increased productivity for enterprises," says John Hurlbert, vice president of product management for M2M at Novatel Wireless. "Over the past three years, data pricing has dropped. As the cost of devices and airtime has declined, other segments, such as security, have benefited by being able to connect millions of wireless endpoints."

Remote Servicer Offers

Fewer Truck Rolls, More Revenue

For organizations using remote management/M2M technologies,

the benefits typically come through faster service

response times and issue resolution, improved usage

and utilization tracking, the ability to perform remote

maintenance and software updates, and a decrease in

staff time spent on the road tending to assets. Aberdeen

found that best-in-class companies that leveraged connectivity

resolved issues on first visits 75% of the time,

compared to 66% for organizations that did not.

According to Murphy, typical benefits among Axeda's customer base have included a 70% reduction in issue resolution time, a 20% increase in product availability, and a 15% increase in contract renewal rates, with remote resolution eliminating thousands of truck rolls. Since each truck roll can cost thousands of dollars (depending on the industry), resolving problems without dispatching a technician can lead to big cost savings.

Proactive maintenance is another benefit. "You can improve the performance and reduce the downtime of remote assets by identifying when servicing is required before failure occurs," says Wayne Stargardt, vice president of service planning and delivery at Numerex. "Oil and gas production equipment, wastewater reclamation systems, and portable generators are examples of assets that can benefit from predictive maintenance."

Once remote management technology is in place, companies often find they can create new value-added service offerings, increasing their revenues in the process. That includes proactive service contracts, improved product uptime guarantees, and automatic consumable resupply with just-in-time delivery. In addition, companies glean valuable information from real-time monitoring that can improve future product development.

Usage-based billing is another offering that has gained popularity. "Financially savvy companies are looking to their suppliers to sell machines based on use or output rather than as capital equipment," says Murphy. "This requires an accurate, auditable mechanism to track operation provided by a direct connection between the service provider and the device. Advanced remote management solutions can provide the platform to manage and measure this usage."

How To Handle A Flood Of Asset Data

One of the chief challenges of implementing an M2M

solution is managing the potential flood of product

data generated by connecting hundreds (or thousands)

of assets to the enterprise. But managed correctly, that

information can improve customer service and generate

important insights into asset performance in the field.

"The primary objective should focus on solving key business problems by determining a projected ROI for the solution and enabling it with connected devices," says Stargardt. "Connecting devices may provide additional data; however, there should be a solid plan for converting the data into useful information, then into business actions that produce measurable results."

There are advanced connected product management platforms available that have been developed specifically to handle the complex requirements unique to these solutions, including managing multiple types of connections and assets, processing large amounts of unstructured data, and providing enterprise-grade scalability and security. Selecting a solution and properly structuring the use of the application within the company's existing infrastructure will impact the utility of the data.

"I would caution companies against signing lengthy consulting contracts that can cost thousands and take months before they even get to the pilot stage," says Fred Yentz, CEO of ILS Technology. "I would also warn against creating an information silo for their monitoring solution — having to manually move that data into business systems is a recipe for extended customer service delays and potential errors."

Complicated M2M Integrations

Can Create Challenges

The complexity of that integration often keeps companies

from deploying the technology altogether. "Even

getting enough information to successfully source the

bits and pieces of the solution often requires a six-month

learning curve," Yentz says. "Add to that 6 to 18 months

of development time just to prove your business case,

and you can see why some might be reluctant to dive in."

But with costs falling and cloud-based systems eliminating some of the deployment headaches, it's easier to implement these systems now. "Lower device and connectivity costs change the risk and opportunity cost factors," Hurlbert says. "The growing number and level of integrated platforms and solutions is reducing the implementation time, cost, and overall risk of M2M deployments in general. The biggest shift will occur when it is seen as a risk not to implement connected solutions."

M2M Solutions Must Be Scalable

According to the vendors interviewed for this story, one

of the key mistakes companies make during deployment

is that they don't understand the challenges of scale

involved in monitoring 10 devices compared to monitoring

1,000 devices. For companies relying on cellular networks,

there are also cost and management challenges.

"Cellular systems behave very differently from Wi-Fi and ZigBee-based wireless systems," Stargardt says. "It requires a higher level of engineering to design a costeffective solution with pay-per-usage communications like cellular. Companies tend to underestimate the difficulty in managing remotely deployed devices that cannot be easily accessed."

As mentioned above, a trap to avoid is creating an M2M information silo within the company. "When M2M solutions are developed to address a specific need within a company, they can sometimes be treated as departmental issues," Yentz says. "This enables the relevant department to monitor, track, and even interact with the assets in their domain, but limits oversight and integration with existing business processes. This can result in a disconnect between the department and support functions like payroll, trouble ticketing, billing, and more."

Prepare for growth. Determine what quantities and frequencies of data will be transmitted, how file transfers will be managed, and how many users will be on the system at peak times. "Things that don't seem like a big deal at 100 connected devices can become show stoppers when you hit 10 or 100 times that amount," Murphy says. "Dealing with a handful of systems in a lab environment is manageable, but as you move out into the real world and the number of connected systems grows, there are architecture bottlenecks that pop up."

Find ways to leverage asset connectivity to improve business processes and service capabilities. "Most enterprises start with obtaining their previous data through some other data collection mechanism," Hurlbert says. "As a result, they only gain cost savings rather than maximizing the capabilities and adding value to the total solution. Evaluating and changing business processes allows enterprises to realize the full potential of a connected solution."